Precision In Every Detail, Excellence In Every Solution

- A Ruiter Innovations Brand

Delivering Solutions

“Pella Electronics' (Ruit BrewTech®) array of equipment has been an integral part of our systems for years. In addition to providing a quality product and streamlined solutions for our weighing and batching needs, their friendly service is top-notch, and their lean and efficient operation ensures that our orders are on-time and on-site when we need them. Whether it's a brewery or a distillery or a feed operation, Pella has a product that will suit your needs.”

- Rusty Riley, Founder and President of MaltHandling.com, LLC

“Thank you Pella (Ruit BrewTech®) for the peace of mind your product offers all of us here at the Brewery. We trust the integrity of your product, which allows us to do our jobs with efficiency and accuracy. Your customer service has been spot on as well. Thank you!”

- Jackie O's Brewery

About Us

At Ruit BREWTECH® our vision is to help breweries maximize efficiency, accuracy, and output while reducing overall time and cost to maximize your output with automated malt metering. Our manufacturing facility is located in Pella, Iowa.

Established in 1993, Ruit BrewTech® Flowscales® quickly became an essential part of any breweries malt handling. Our Ruit BrewTech® Flowscales® are 99% accurate and have proven time and again to be much more accurate than manually fed systems. Many customers have praised how much manual labor our Flowscales® save, and many brewery employees have been thankful for us saving their backs. After all, lifting 50-pound bags of malt 40 hours a week certainly causes some back issues.

We take pride in being American made. All of our products are designed and manufactured in Iowa. This helps provide jobs for Americans and promotes the mindset of doing things here in the USA and doing them right.

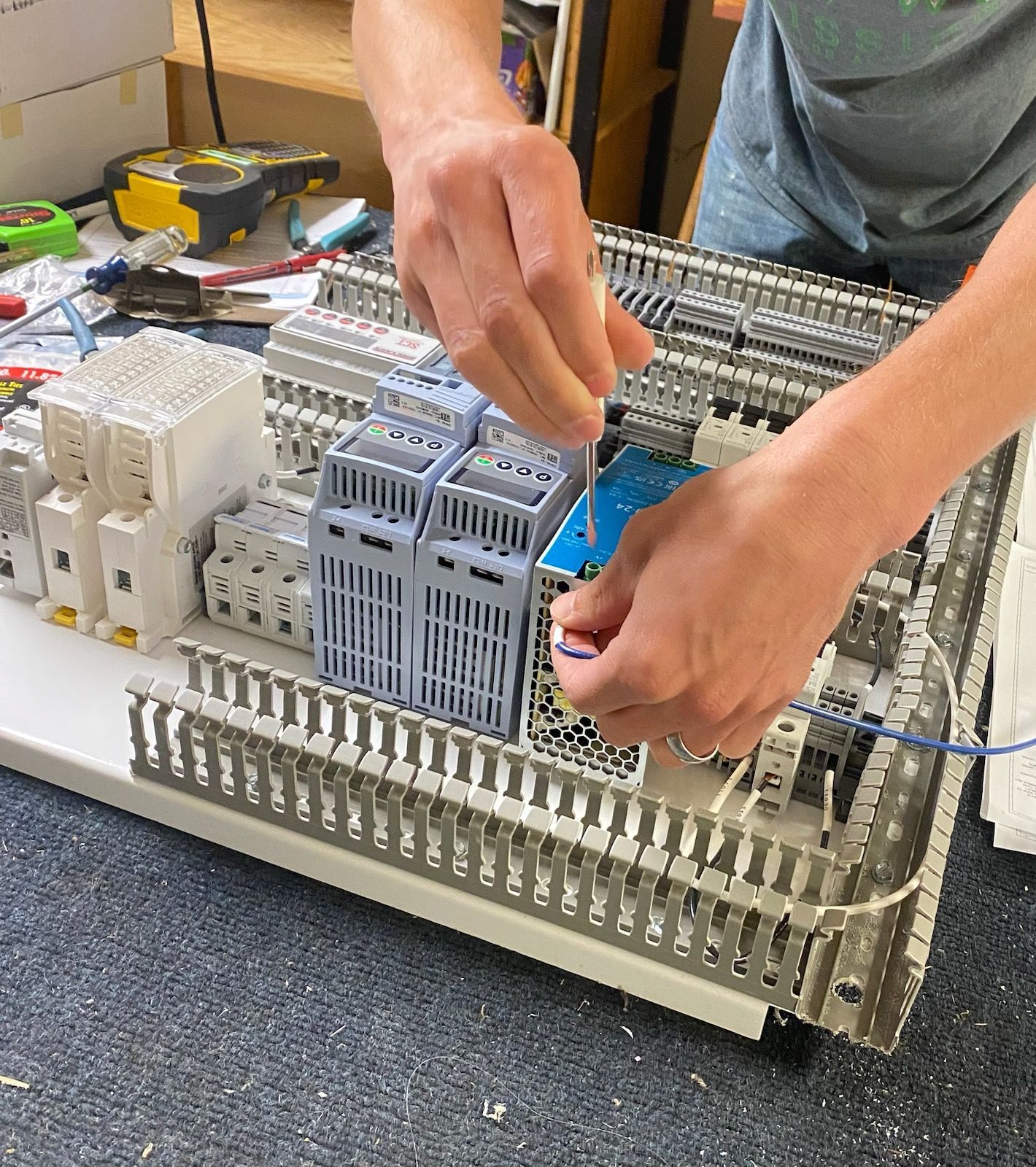

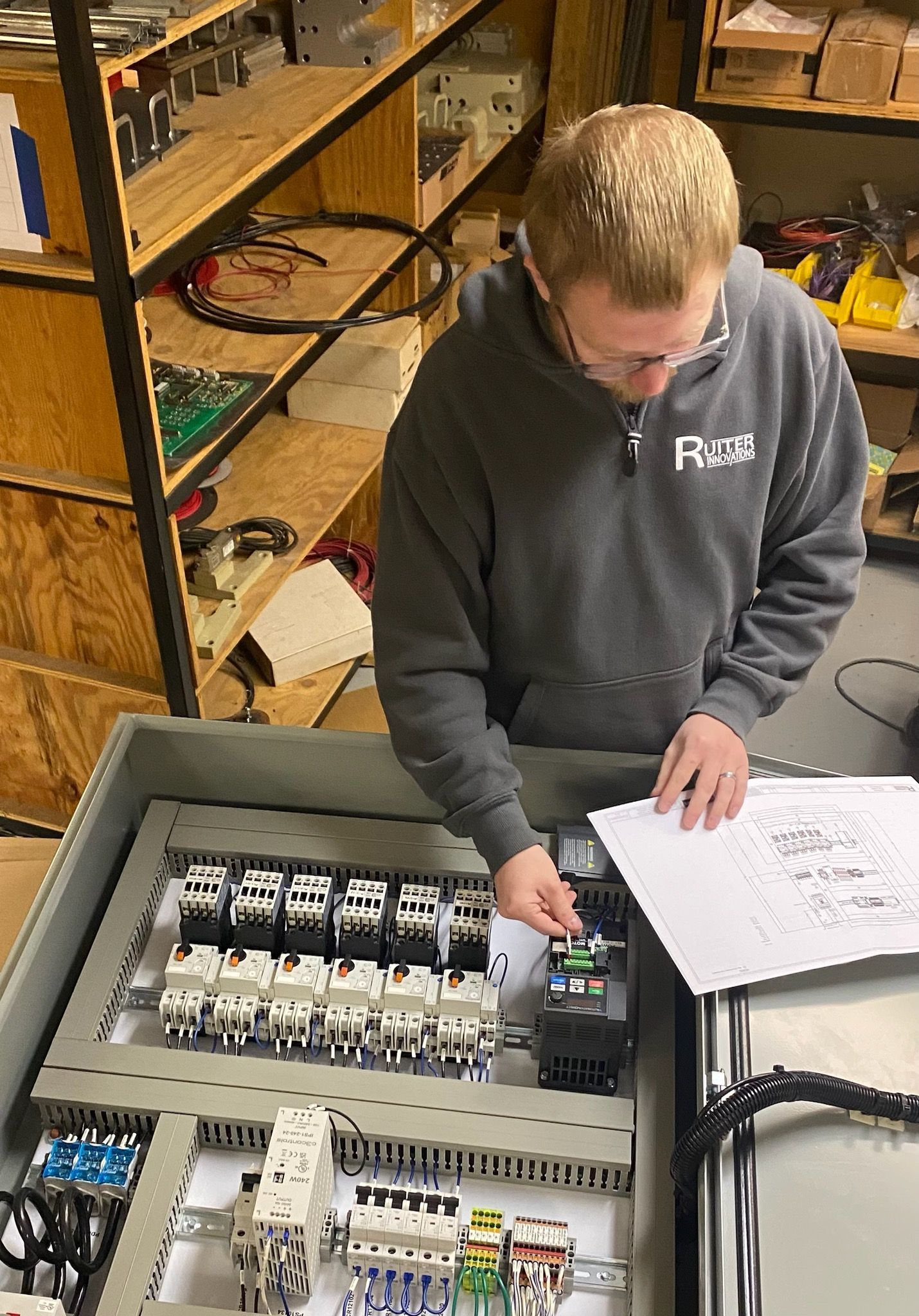

We are excited to announce that 2022 marks the next generation of our company. We are completely overhauling our technology and capabilities. This will include touch screens, PLCs, and the capability for end-to-end brewery controls. Automate everything from one place (our Control Center)! Stay tuned for details, images, pricing, and more!

Our Team

Jeff Ruiter

CEO/Owner

I come into this new branch of business with a love of the brewing/distilling industry and 30 years of experience in manufacturing and leadership. Excelling at every opportunity in new product design and development, I thrive in and enjoy being a business transition and growth leader.

Lisa Ruiter

Office Manager/Owner

I have enjoyed part-time work in administrative roles while raising our children. As our youngest turned 18 years old we were given the opportunity to purchase a local business that was family owned. It has been a wonderful transition and so much fun to work closely with my husband, our sons, while also meeting existing partners and new customers across the country and internationally. It has also been a huge blessing to give back to our community that has poured into our lives for the last 37 years.

Billy Graves

Chief Technical Officer (CTO)

With a focus on understanding each customer's unique challenges, Billy Graves's role at Ruiter Innovations, the mission is clear: to bring transformative technology to the material handling industry. By integrating automation, the goal is not just to implement technology but to empower users, making complex systems accessible and manageable.

As Billy Graves leads the charge at Ruiter Innovations, the commitment to continuous improvement remains unwavering. The journey is marked by a dedication to simplicity, ensuring that technology not only enhances operations but is user-friendly and approachable. Billy Graves believes in the potential of technology not to replace but to elevate, creating a future where automation is a catalyst for progress.

Join Billy Graves on the forefront of automation, where a blend of expertise, innovation, and a genuine understanding of customer needs converge to shape the future of industry.

Our Timeline

1987

Company Formed

1988

Digital Scales

1990

FS300 Batching System

1993

Feedpro System Introduced, followed by The LX800 Micro System, Liquid Fat System, and Software to control the system. These systems allowed for the automation of the feed making process.

1993

Flowscale Introduced – More specific flow rate for a specific measurement purpose. These are used in many industries, but the most heavily in the brewing and distilling industry.

2020

The Company was purchased by Jeff and Lisa Ruiter and began doing business as Ruiter Innovations.

2022

The Ruit Brewtech Product Line is introduced moving from the original circuit and motor boards to systems the are run via PLC and VFD.

2023

Launched the GHP 8000 as an entry level digitally controlled weighing system for new or smaller breweries and distilleries.

Why Accuracy Matters

FEEDPRO is your “best cost” choice for a feed system, because AgtronixTM offers more automation and quality feed-making features for your money. By utilizing continuous flow blending by weight, the FEEDPROTM provides precise mixing with minimum labor and low equipment overhead cost. AgtronixTM builds systems with the latest technology that will perform better for you.

UNIQUE FEATURES of the FEEDPRO

Eliminates so much of the equipment that is involved with installing a batch style mixing system.

Accuracy – Brewtech